Close

Excellence in heating process arena through

indigenous,

ground breaking Infrared Heating Technology.

Litel’s customized solutions benefited 500+ happy customers across industries such as automobiles, auto components, composites, foundries, paper, textile, pumps, valves, rubber and space research. The major objectives of all the customers have been met with respect to optimising the energy savings, increased productivity and precise controls over thermal processes.

Industry 4.0

As the technology evolved to address the inefficiencies in heating process, Litel has provided the right heating solutions by aligning to Industry 4.0 for each process, optimising for energy efficiency and costs. Litel solutions are elegant, low maintenance, environmental friendly design for consistent and uninterrupted operations. Litel’s expertise in thermal engineering, control engineering, automation and air handling systems has enabled tailor made solutions considering space and energy constraints.

Litel R&D Laboratory is DSIR (Government of India’s Department of Scientific & Industrial Research) certified which is a rare honour. We are also ISO 9001:2015 certified. Our prototypes of IR heating systems and sophisticated controls enable to determine parameters for problem solving and arriving at correct solutions even before building the actual equipment. This approach mitigates risks in the actual production processes.

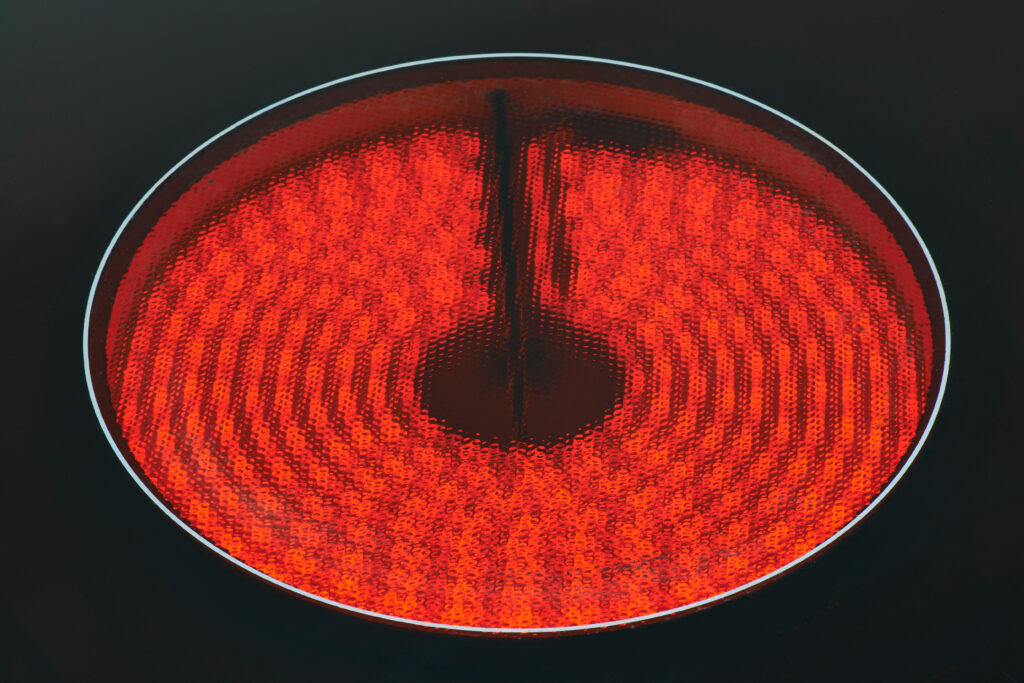

B-IRD (Better Infrared Rotary Drum)

Developed at Litel R&D Centre in cooperation with the German inventor of Infrared Rotary Drum (IRD) technology, B-IRD is a step up over large scale IRD processing and comes with a world wide patented revolutionary drum design for enhanced particle agitation and flexible heating. The simple, ultra fast B-IRD Labtop, with high flexibility enables small scale production of valuable bulk materials, achieve new benchmarks and energy efficiency in processes.

Reducing the footprint

Litel brought about the transition from traditionally bulky, grimy, high maintenance industrial ovens to the clean, convenient infrared ovens, so sleek that they may be mistaken for consumer durables. Not only is our equipment low on emissions, it also occupies a smaller physical footprint.

B-IRD (Better Infrared Rotary Drum)

Developed at Litel R&D Centre in cooperation with the German inventor of Infrared Rotary Drum (IRD) technology, B-IRD is a step up over large scale IRD processing and comes with a world wide patented revolutionary drum design for enhanced particle agitation and flexible heating. The simple, ultra fast B-IRD Labtop, with high flexibility enables small scale production of valuable bulk materials, achieve new benchmarks and energy efficiency in processes.

Reducing the footprint

Litel brought about the transition from traditionally bulky, grimy, high maintenance industrial ovens to the clean, convenient infrared ovens, so sleek that they may be mistaken for consumer durables. Not only is our equipment low on emissions, it also occupies a smaller physical footprint.

Our Electric IR Product Line

Our extensive range of infrared ovens and dryers offer the highest accuracy in their class. Quartz Infrared emitters, Panel emitters and other combinations cover the entire infrared spectrum spanning from near infrared and shortwave infrared to medium and longwave infrared. Also in our product portfolio are radiant infrared and gas catalytic infrared burners, floor conveyors for different object weights, overhead motorised track and trolley conveyors and pneumatic retraction systems.

Our solution package comes with cutting edge, integrated, specialised control systems. Made to national and international standards, they provide actual product temperature sensing and solid state power regulators for fine control in the 0-100% range. Also included are PLC, SCADA or other digital platforms for complete automation, remote control and integration with other equipment.

Infrared emitters manufactured to global standards and exported to advanced countries like UK, Germany & USA.

We are proud to say that apart from NASA, Litel is the only provider with complete setup to develop extremely high intensities of infrared radiation (up to 5 MW per sq m) for aerospace applications for rapid thermal process.

Implementation of complex computer-generated temperature profiles required for aerospace applications in actual physical systems

We offer Gold reflectors on IR emitters which are done till now only in Germany, to increase the reflectivity of IR energy to 99% to yield substantial energy savings. This process is also extended to gold coated metals which enables customers to reduce huge running costs.

Absolute uniformity in heating across glass plates and plastic thermoforming.

Extraordinary time cycle reductions for many web-drying processes and paint curing processes through IR designs.

Reduction in power consumption to the tune of 30% in textile screen-printing drying application.

Uniform air and product temperature control achieved for non-conducting composite resin material as well as drying water-based coatings with reduced cycle times.

Infrared emitters manufactured to global standards and exported to technologically advanced countries like UK, Germany & USA.

We offer Gold reflectors on IR emitters which are done till now only in Germany, to increase the reflectivity of IR energy to 99% to yield substantial energy savings. This process is also extended to gold-coated metals which enables customers to reduce huge running costs

We are proud to say that apart from NASA, Litel is the only provider with complete setup to develop extremely high intensities of infrared radiation ((up to 5 MW/m2) for aerospace applications for rapid thermal process.

Implementation of complex computer-generated temperature profiles required for aerospace applications in actual physical systems

Uniform air and product temperature control achieved for non-conducting composite resin material as well as drying water-based coatings with reduced cycle times

Gas Infrared Burners, with the same interesting features as electric IR emitters, are now being manufactured in India

Extraordinary time cycle reductions for many web-drying processes and paint curing processes through IR designs

Reduction in power consumption to the tune of 30 % in textile screen-printing drying application.

Absolute uniformity in heating across glass plates and plastic thermoforming

Optimise your heating process with customised solutions from our experts