Is there a magic wavelength?

Very often prospective users of IR heating equipments are baffled by conflicting claims of IR equipment manufacturers as to how one particular wavelength is “superior” to another. Most manufacturers make only one particular type of infrared heater and hence they tend to twist scientific facts to support their claims. We at Litel are most fortunate to have the entire spectrum of IR wavelengths in our manufacturing range and hence are in a position to present an unbiased analysis.

Wavelengths

We all know the visible light ( violet to red vibgyor ). Beyond the red lies the invisible Infrared. The useful range of infrared which lies between 0.7 microns to 10 microns

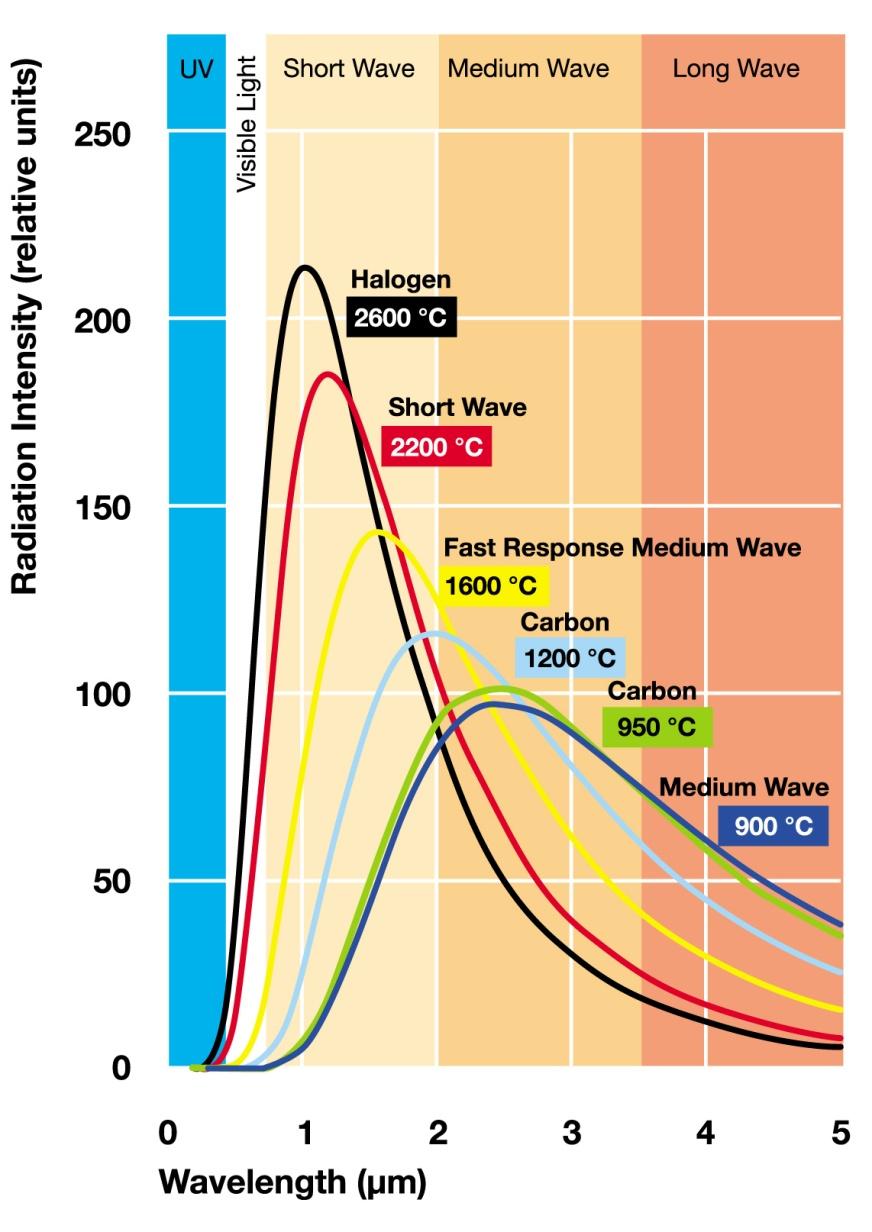

A typical distribution of power across the spectrum is given here.

Peak wave-lengths

Peak wavelength of an emitter is the wavelength at which it emits maximum amount of energy.Some typical peak wavelengths are as follows:

Near Infrared: 0.8-1 micron

Short-wave IR : 1.0-1.4 microns

Fast-medium-wave: 1.4 – 1.7 microns

Medium-wave : 1.7 – 2.5microns

Long-wave:2.5 – 3.1 microns

Sometimes long wave IR is also mentioned as Far Infrared.

1. IR emitters always emit IR over a range.

2. The ranges given here are as accepted by Litel. This classification is approximate.

3. The spectrums overlap each other.

1. IR emitters always emit IR over a range.

2. The ranges given here are as accepted by Litel. This classification is approximate.

3. The spectrums overlap each other.

Some Comparative Analysis

- Radiant Efficiency.

Shortwave has the highest radiant efficiency ( 86-90%) i.e. conversion of electricity to infrared. Thereafter it goes down both ways.

- Rate of heat transfer

NIR and Shortwave have the highest rate of heat transfers and are capable of raising metal temperature at the rate of 100 ⁰C / second. Long wave has the lowest rate of heat transfer within IR spectrum.

- Penetration

IR does not directly penetrate metal beyond a few microns. However IR does penetrate into coatings and synthetic materials and Shortwave has the highest penetration properties.

- Colour Sensitivity.

All radiation is colour sensitive. Shortwave, on account of its highest radiant efficiency, is more colour sensitive. Medium wave quartz also shows some sensitivity. However this factor does not matter in practice as at a time only one type of product is processed and ovens/ dryers controls are designed to take care of variation in process parameters.

Is Selective Absorption Valid?

This theory has limited applications, mainly due to the fact that any emitter esp. medium and long wave emitters emit a very small percentage of their energy around the absorption maximum. It is only in certain material heating applications e.g. in some thermoforming applications medium / long wave have been proven to give better results. But even in thermoforming, shortwave has given excellent results and for PET blow moulding, despite PET being a plastic material shorter wavelengths are used on account of their penetrability. Also, when heating paints / powders / coatings on metals, this absorption spectrum is not of much relevance as other factors become predominant.

How to select the wavelength?

There is no “magic wavelength” suitable for all processes.

In fact even for the same process wavelength can change due to operational conditions

Absorption characteristics are important in only a few specific cases.

Generally for processes requiring very short heating times such as rapid thermal testing (less than 30 seconds) paper coating immobilization (less than 100 milliseconds) etc, Near Infrared / shortwave is a clear choice.

For most other applications the choice of wavelength is highly influenced by operating conditions such as:

- Quality of the processed product

- Space constraints and the layout of plant

- Throughput requirements

- Controllability and control accuracy

- Compatibility with automation requirements, Etc